Equipment functions and parameters

Thick film with a width of 1m and a length of 1.6m can be spun, with a thickness of 30-2000μm and a spinning speed of 1000μm/hr. It can spin up to 6 kinds of spinning solutions at the same time. System; digital display control, real-time monitoring of substrate moving speed, temperature and humidity, voltage and current; negative pressure cavity design to prevent organic gas leakage; grounding system, emergency shutdown, short circuit protection, overvoltage protection, overcurrent protection, safety lock, Explosion-proof glass, warning system and other safety settings. This type of equipment has a wide range of uses in thermal insulation, functional fabrics, electromagnetic shielding, filtration, etc.

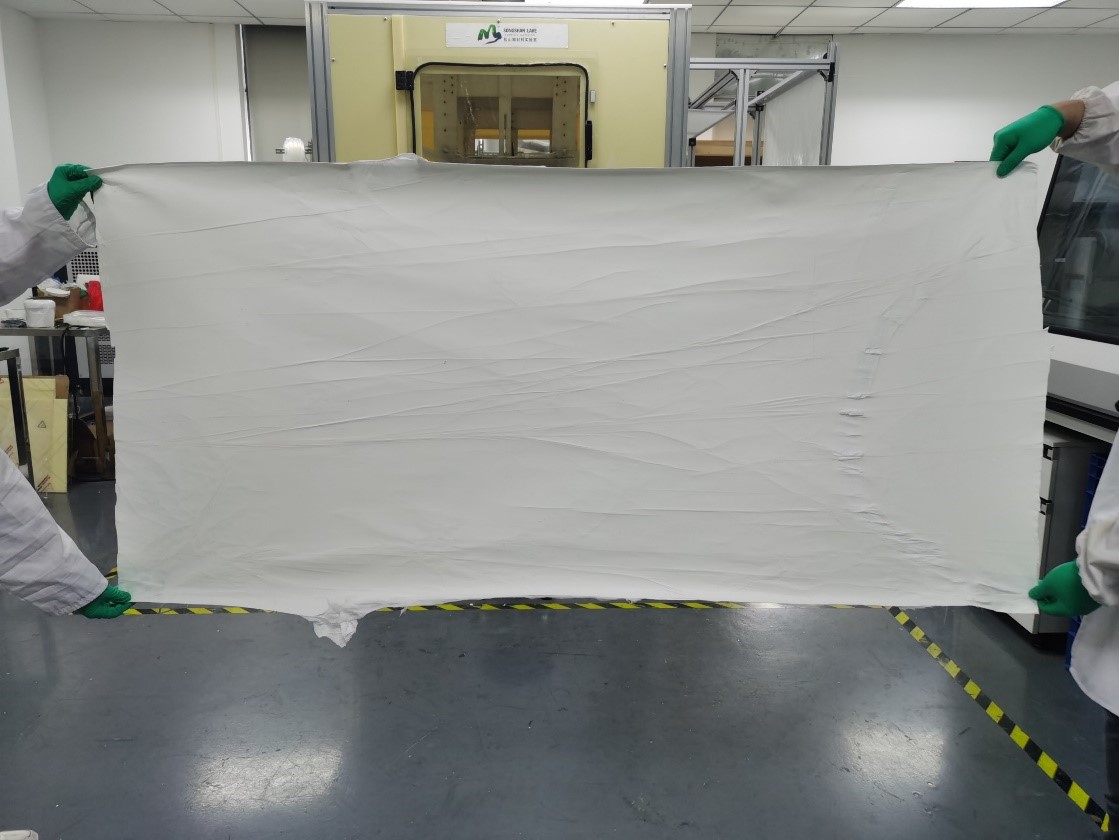

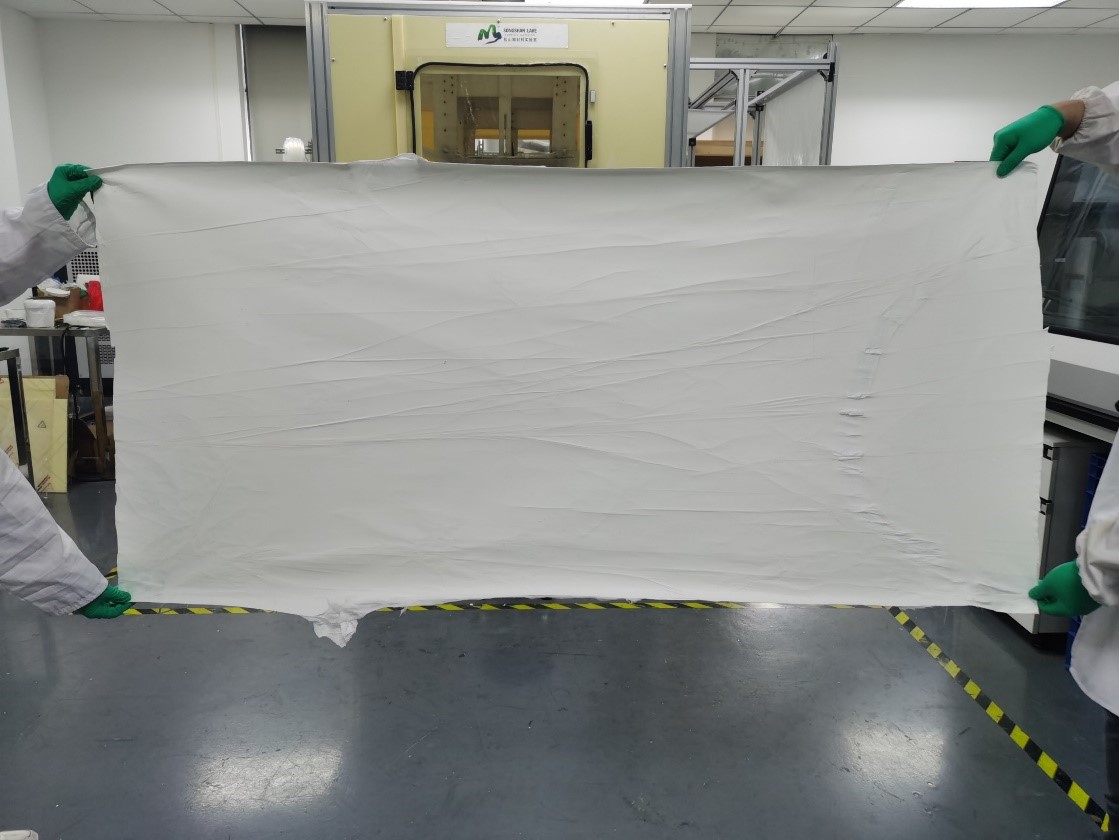

1m×1.6m self-supporting thick film

parameter configuration

High voltage power supply

(1) Built in the control panel on the left side of the device, the panel displays real-time voltage and current;

(2) 2 power supplies (domestic): adjustment accuracy 0.01kV (DC);

(3) 1 set of positive power supply: 0~+30kV (provided for the use of the bottom rotating nozzle);

(4) 1 set of negative power supply: 0~-30kV (for switching use of all receiving devices on the upper part, directional traction collection);

(5) Display mode: digital display;

(6) Protection mode: current automatic overload safety protection;

(7) Control method: manual;

sprinkler

(1) Independent detachable rotating nozzle, with a special device for adjusting the tension, and a roll of spare metal wire is randomly configured;

(2) Effective working length: 1000mm;

(3) Adjustable rotation speed: 0~140rpm;

tank

(1) 1000ml special electrospinning solution tank, machined to prevent leakage, easy to clean;

(2) The number of liquid tanks can be optionally expanded to five to improve the spinning efficiency;

receiving device

(1) Tape-and-reel collection device: moving speed 0.33~600mm/min;

(2) Size: width 1000mm, circumference (length) 1600mm;

(3) The negative electrode receives the voltage with built-in safety insulation;

Receive spacing to move components up and down

(1) The upper limit of the spacing can be adjusted to meet different spinning needs;

control device

(1) Digital display industrial control, integrated in the equipment panel, knob digital display control, real-time response to parameter changes during the working process without stopping;

(2) It can control the rotation of the nozzle, and the receiving and rotating device can operate together or independently;

Environmental control

(1) Integrated industrial dehumidifier built-in;

(2) Space humidity: 30% to 80%, the humidity can be controlled continuously;

(3) Space pressure: normal pressure;

(4) Space sealing: the spinning chamber is sealed as a whole, and the operation door is hydraulically assisted;

accessories

(1) Micro LED observation light;

(2) Air outlet (with ventilation hose pipe, length 2m);

(3) High-volume ventilation fans at the top (flow rate ≥ 150m3/hr);

(4) Maintenance/use toolbox (including supporting tools);

safety devices

(1) Power supply overvoltage protection;

(2) Power overcurrent protection;

(3) Work running warning lights;

(4) Data memory recovery after power failure;

(5) Emergency stop button;

(6) Large size explosion-proof tempered glass observation window;

Dimensions

(1) Dimensions: 138(W)×208(L)×212(H)cm;

(2) Shell material: aluminum alloy frame, PP insulating shell, electrospinning chamber with special insulation treatment;

(3) Weight: about 200kg;

(4) Power supply requirements: 220V, 50Hz;

(5) Rated power: ≤1000W;

|

Warm tip: the products supplied by Beijing Beike Xincai Technology Co., Ltd. are only used for scientific research, not for human body |

| Item ID |

CAS |

ID |

Pack |

Parameter |

Stock |

Make up |

Price |

| BK2022022307 |

|

BK2022022307 |

台 |

|

100 |

|

$0 |